With more than 40 years in the special application vehicle industry,

- Plot No 1H-42A, Phase 1, Hamriyah Free Zone Sharjah, UAE

- Office Timing: 9am to 6pm

The automotive industry is changing very rapidly. Now, innovative and brainy engineers are concerned about reducing the production costs of vehicles as well. The demand for lightweight and strong material is rising exponentially. There are multiple advantages of switching to lightweight and advanced materials. When the weight of the superstructure is reduced, the engine consumes less fuel. A reduction of 5 to 7% certainly matters. Additionally, get a better payload of the vehicle. You must learn about the polypropylene advantages. A fuel efficient vehicle is safe for the environment as it emits less pollution.

Heavy vehicle manufacturers have already switched to light materials like high-performance plastic and aluminium. Vehicles made up of lightweight materials are easy to drive, but the best part is their durability is not compromised. The advantages of using polypropylene in automotive manufacturing is now well-known. Let us know what makes it an obvious choice for the automotive industry:

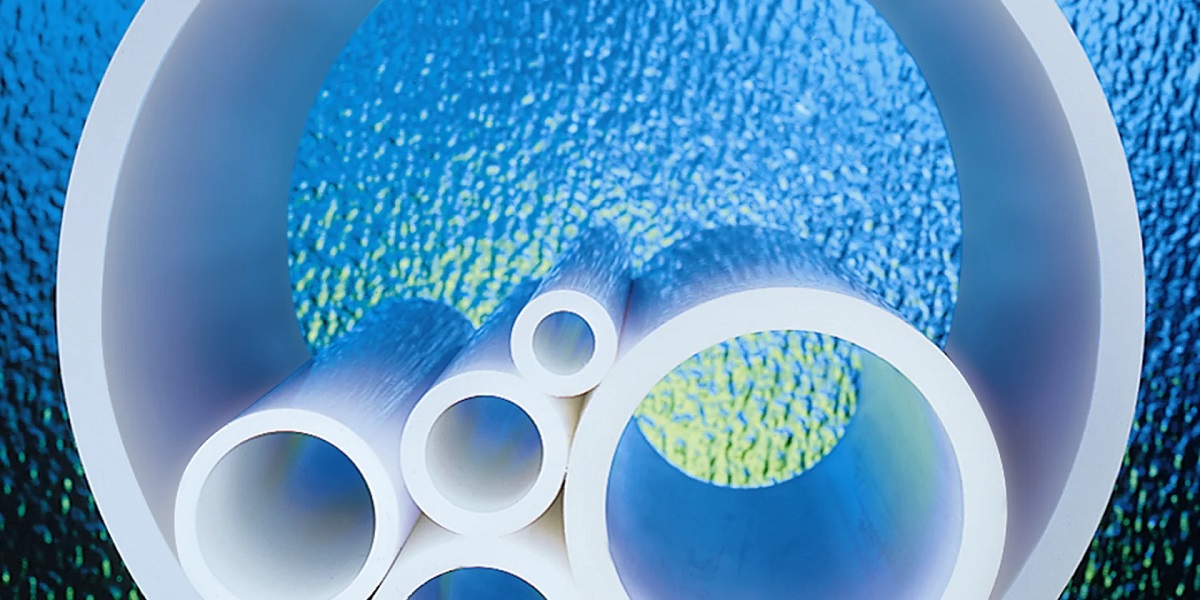

Polypropylene is extensively used for making tanks, shelves, brackets, bumpers and other superstructure components. In new technology, we are developing Modular Polypropylene Body Concept, where a complete body of Fire & Rescue Trucks is being designed and made from Polypropylene sheet which can be ready to mount on any available chassis.

The automotive industry had identified the advantages associated with their material long back. Polypropylene is used for making bumpers, claddings and several internal components such as the dashboard, consoles, seatbacks, door panels, etc. As manufacturing technology is making progress, new types of synthetic materials are being invented. They are helping several industries and especially the automotive sector. Modern heavy-duty vehicles such as trucks are made of the latest materials. The manufacturers are aware that the usage of the latest lightweight materials is a big boon. Needless to mention, high-performance plastic and synthetic products are likely to attain popularity in the coming future. They will also reduce our dependence on availability of materials such as metals.